Als führender Betrieb in Europa verstehen wir unser Handwerk

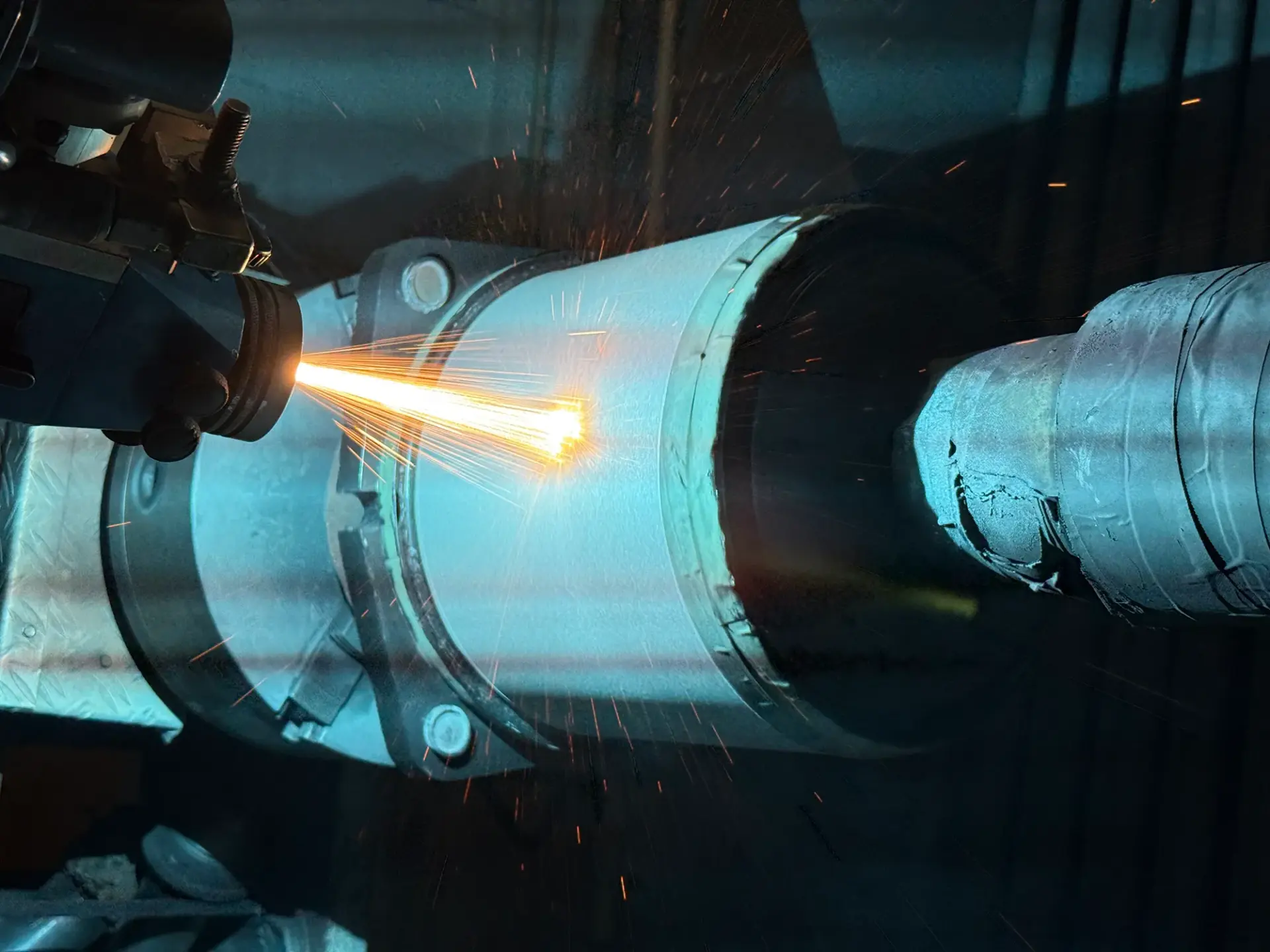

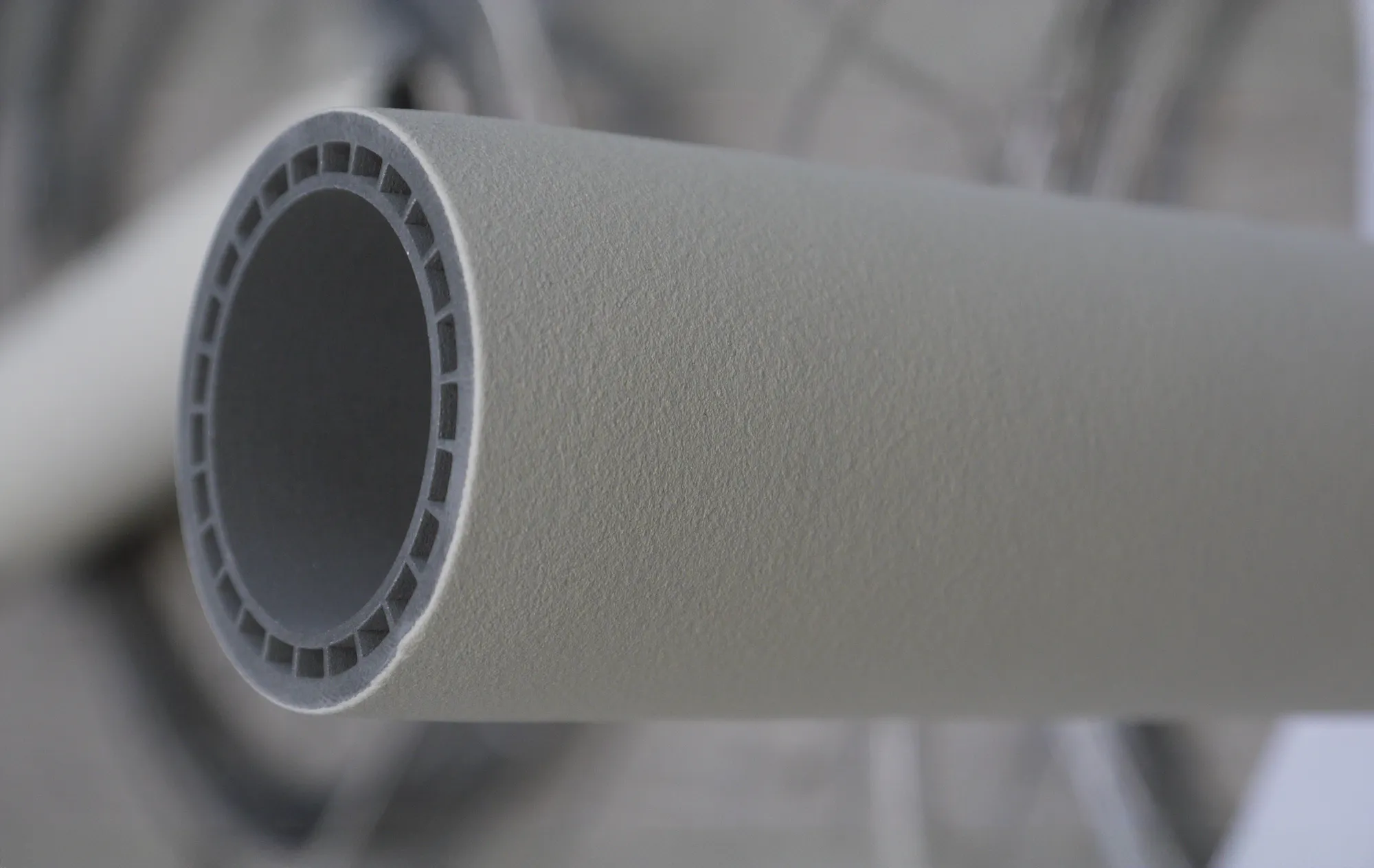

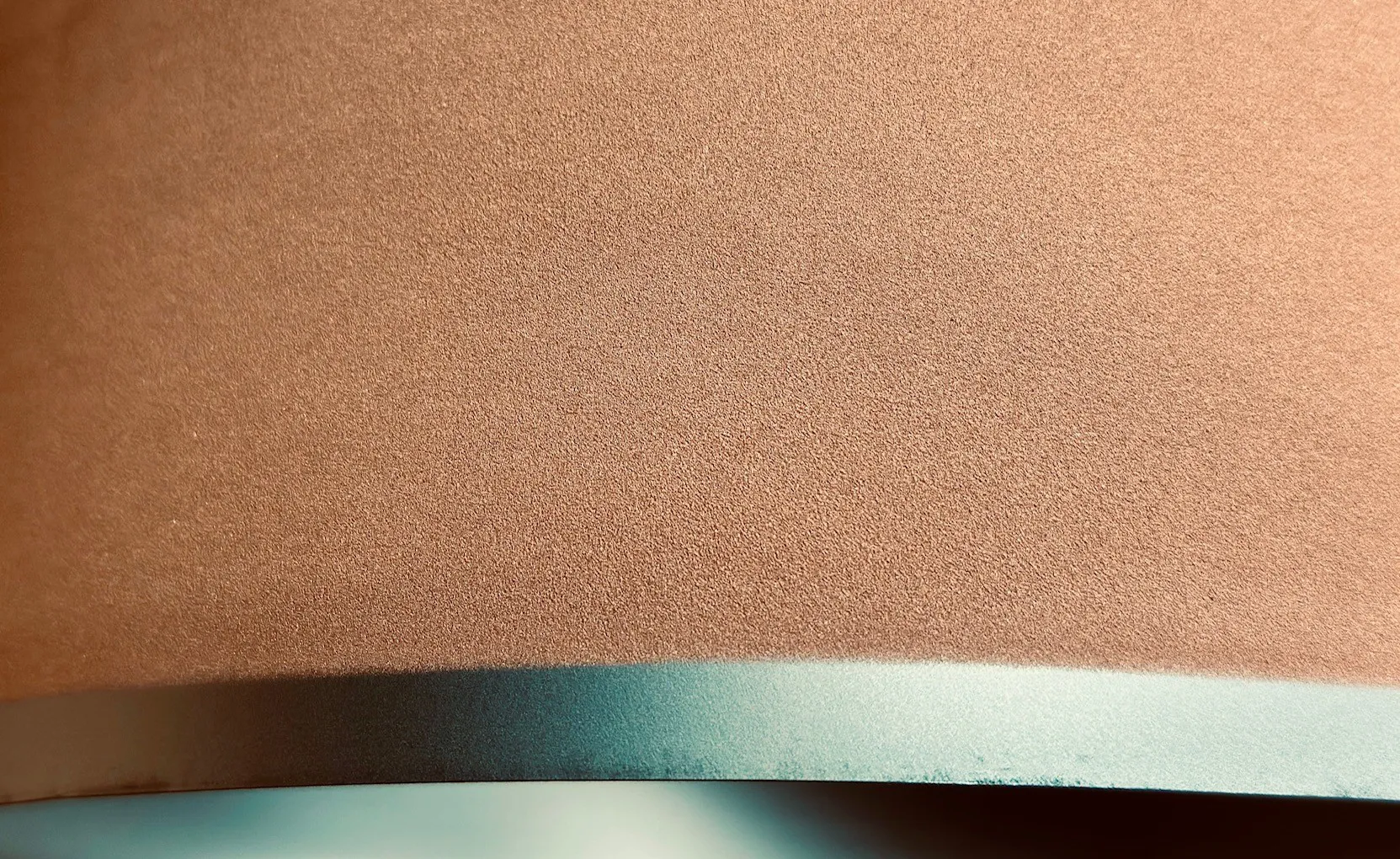

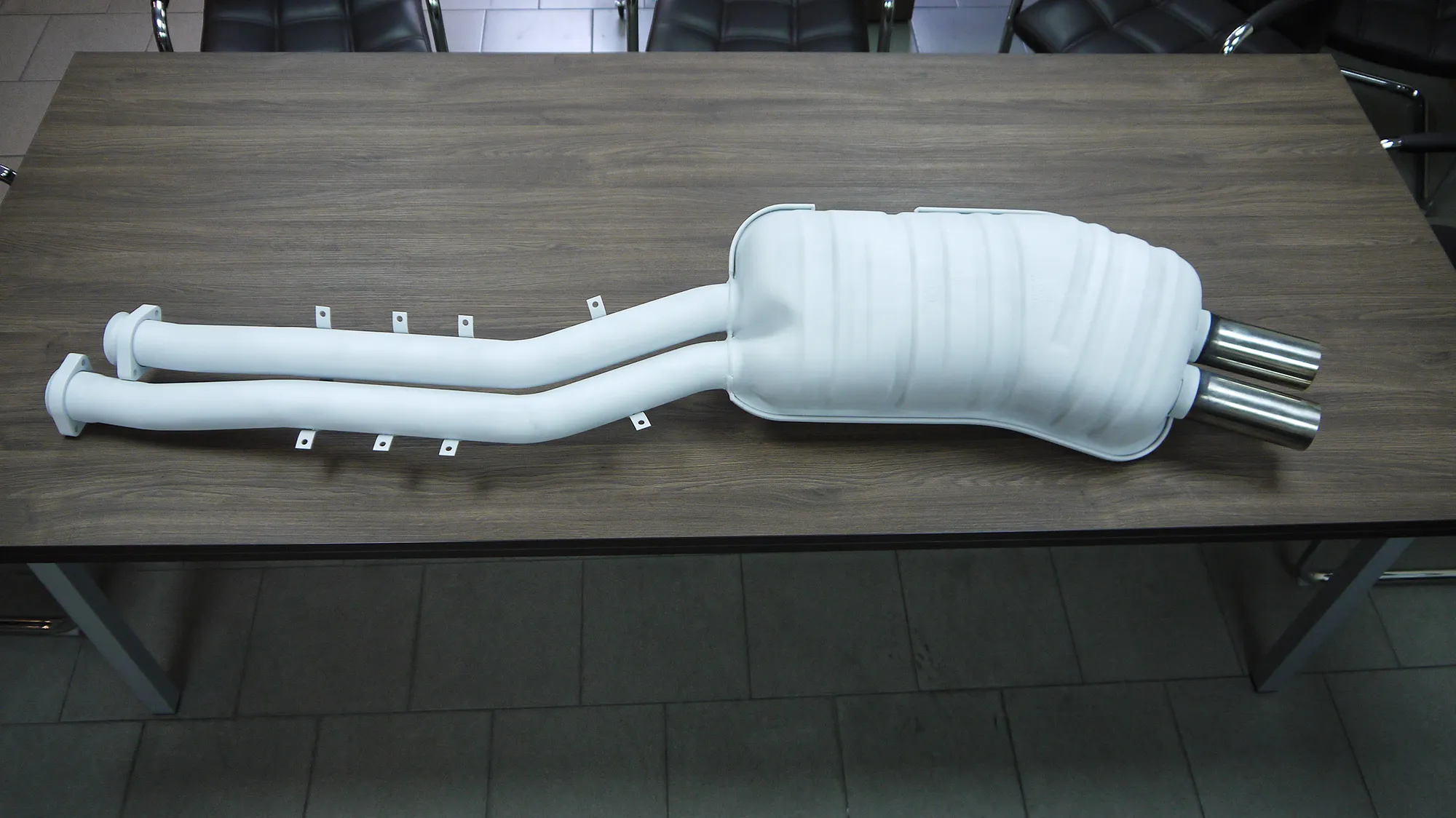

Aus dem handwerklichen Kleinbetrieb der Jahre bis 1990 hat sich das Unternehmen seit 1993 zu einem der technologisch führenden Betriebe der Thermischen Spritztechnik in Europa entwickelt.

Dabei stützt sich die technologische Überlegenheit des Unternehmens sowohl auf die langjährige Erfahrung der seit 1948 ausgeübten Tätigkeit des Thermischen Beschichtens als auch auf die Tatsache, dass alle verbleibenden Gewinne in die Investitionen modernster Beschichtungstechnik, der Robotertechnik, von Rationalisierungsmaßnahmen und in die Weiterbildung der Mitarbeiter fließen.

Unser Angebot für Unternehmen und Privatpersonen

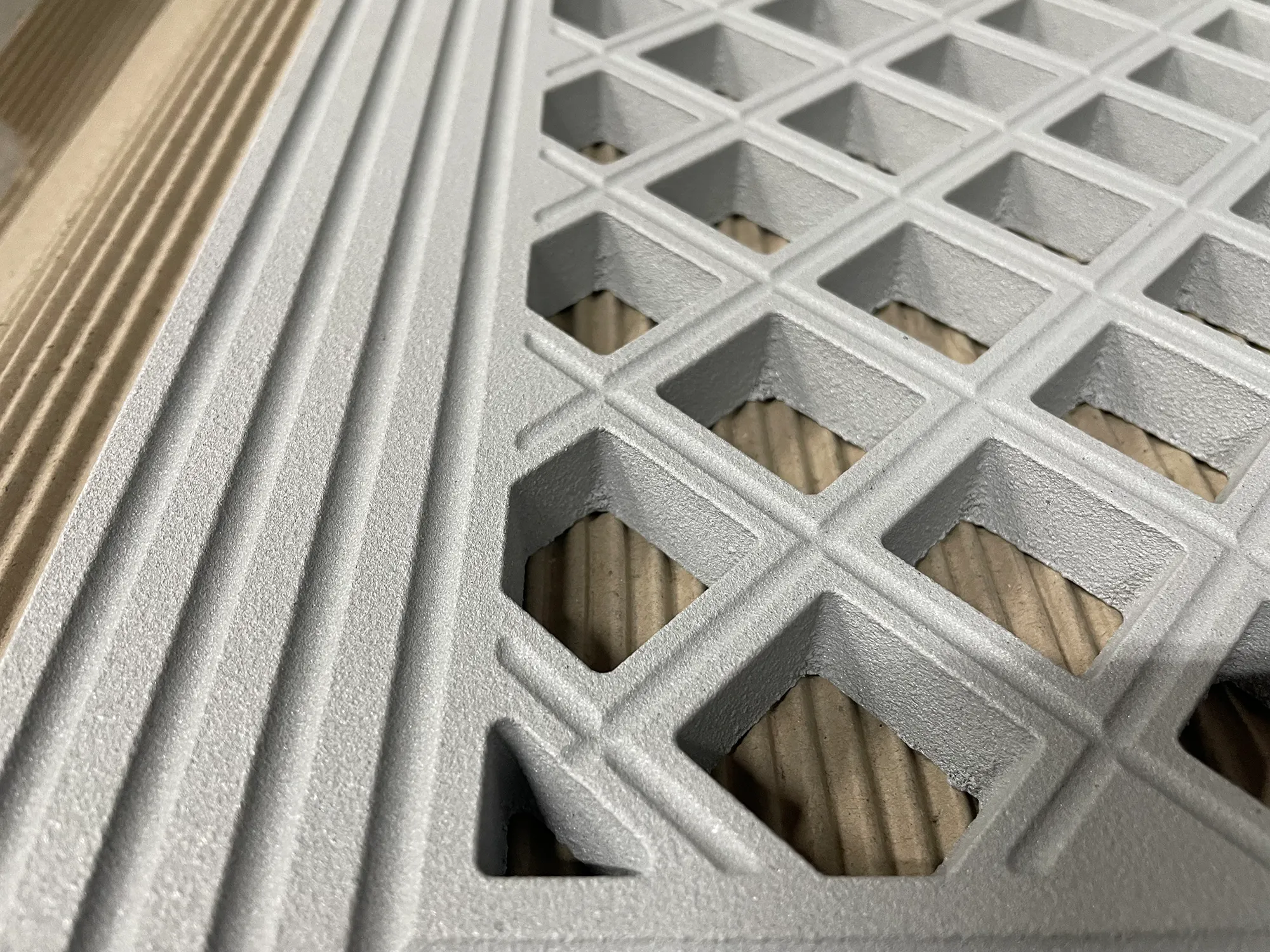

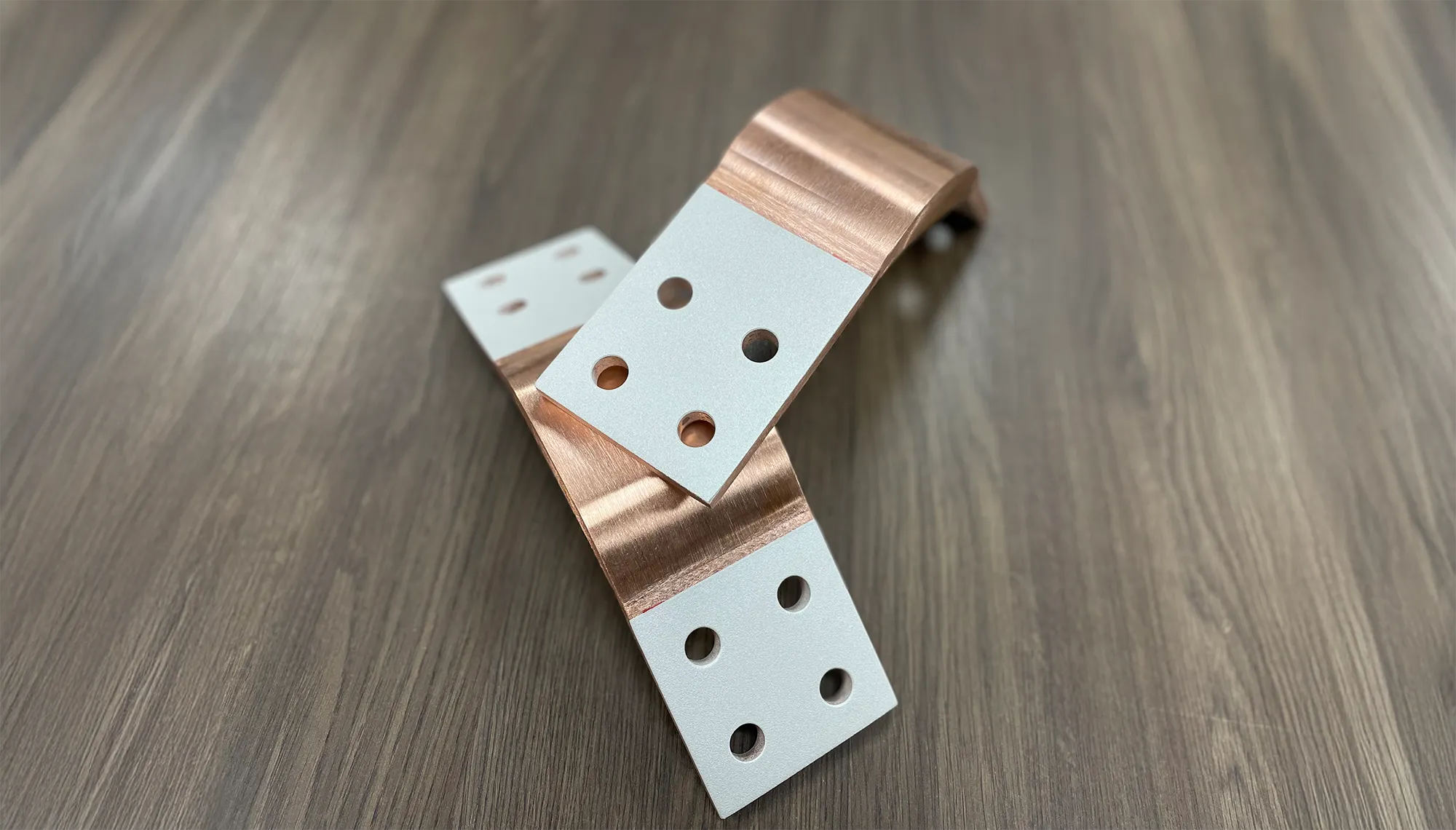

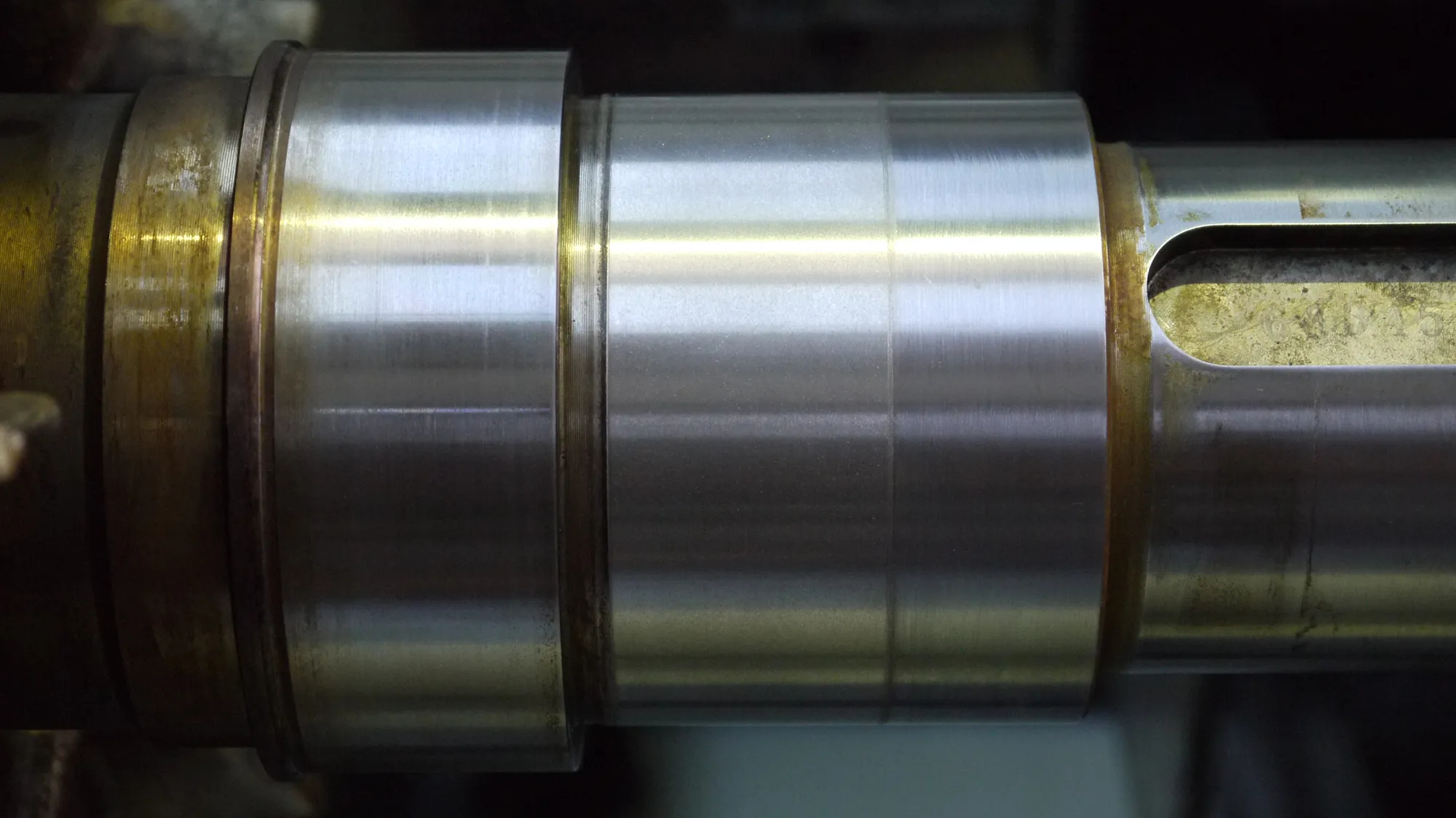

Die Berolina Metallspritztechnik Wesnigk GmbH bietet ein breites Spektrum an Leistungen rund um thermische Beschichtungen und mechanische Bearbeitung. Das Unternehmen ist sowohl für Großaufträge von großen Unternehmen als auch für Anliegen von Privatpersonen der richtige Ansprechpartner.

Neben der Reparatur von verschlissenen Maschinenteilen und der Rettung fehlbearbeiteter Teile bieten wir auch die Verbesserung von Oberflächeneigenschaften an Neuteilen an. All diese Leistungen finden in unserem umfangreichen Maschinenpark statt.

Wir suchen Dich!

Aus dem handwerklichen Kleinbetrieb der Jahre bis 1990 hat sich das Unternehmen seit 1993 zu einem der technologisch führenden Betriebe der Thermischen Spritztechnik in Europa entwickelt. Nun suchen wir dich als tatkräftige Unterstützung – Quereinsteiger stets willkommen!

Bewirb dich jetzt in nur 60 Sekunden, als:

- Dreher:in / Zerspanungsmechaniker:in (m/w/d)

- Initiativbewerbung (m/w/d)